Residential Troubleshooting

Residential electrical systems are often simpler than their commercial and industrial counterparts, but they come with their own set of challenges. Homeowners frequently encounter issues like flickering lights, tripped circuit breakers, and faulty outlets. Here's how I tackle these common problems:

Flickering Lights: Flickering lights can be caused by a variety of issues, from loose bulbs to more serious wiring problems. My first step is to check the light bulb itself. If tightening the bulb doesn't solve the issue, I move on to inspect the light switch and the wiring. Loose or corroded connections are often the culprits. Using a multimeter, I check for continuity and voltage drops to pinpoint the exact location of the fault.

Tripped Circuit Breakers: A tripped breaker is usually a sign of an overloaded circuit or a short circuit. I start by identifying which circuit is affected and then unplugging all devices connected to it. After resetting the breaker, I plug in each device one by one to identify the source of the overload. If the breaker trips immediately, it indicates a short circuit, which requires a more detailed inspection of the wiring and outlets.

Faulty Outlets: Non-functional outlets can be due to loose wiring, a tripped GFCI outlet, or a blown fuse. I begin by checking the outlet with a voltage tester. If there's no power, I inspect the wiring and the circuit breaker. For GFCI outlets, a simple reset might do the trick. If the problem persists, I replace the outlet and ensure all connections are secure.

The Art of Electrical Troubleshooting: A Professional Electrician's Perspective

Commercial Troubleshooting

Commercial electrical systems are more complex and often handle higher loads than residential systems. Common issues include overloaded circuits, outdated wiring, and faulty equipment. Here's my approach to troubleshooting in commercial settings:

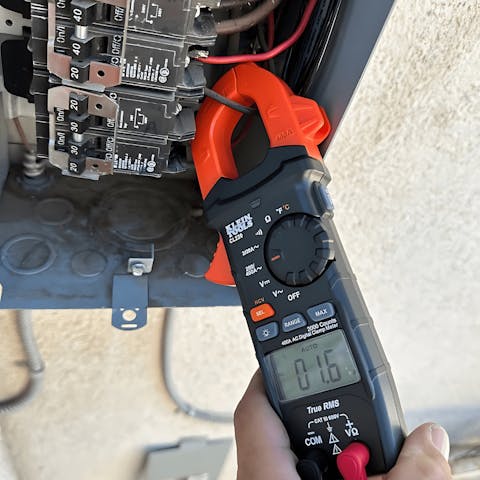

Overloaded Circuits: Overloaded circuits are a frequent issue in commercial buildings, especially in older structures with outdated electrical panels. I start by inspecting the electrical panel for any signs of overheating or damage. Using a clamp-on ammeter, I measure the current load on each circuit to identify any that are overloaded. Upgrading the electrical panel or redistributing the load across multiple circuits can often resolve the issue.

Faulty Wiring: Faulty or outdated wiring poses significant safety risks, including fire hazards. During troubleshooting, I look for signs of wear and tear, such as frayed wires, discoloration, or burning smells. I use a multimeter to check for continuity and voltage drops, ensuring that all connections are secure and up to code. Replacing old wiring with new, properly rated cables is essential for maintaining safety and efficiency.

Faulty Equipment: Commercial settings often have specialized equipment that requires regular maintenance. When troubleshooting equipment, I refer to the manufacturer's manuals and wiring diagrams to understand the system's layout. Using tools like ohmmeters and voltmeters, I test individual components to identify any that are malfunctioning. Replacing faulty parts and ensuring proper grounding are key steps in restoring equipment functionality.

Industrial Troubleshooting

Industrial electrical systems are the most complex and demanding, often involving high voltages and specialized machinery. Safety is paramount, and troubleshooting requires a methodical approach:

High Voltage Systems: Working with high voltage systems requires specialized training and equipment. I always follow strict safety protocols, including wearing personal protective equipment (PPE) and using insulated tools. When troubleshooting, I start by isolating the affected circuit and using a voltmeter to measure voltage levels. Identifying and replacing faulty components, such as transformers or circuit breakers, is crucial for maintaining system integrity.

Motor Failures: Motors are a common component in industrial settings, and their failure can lead to significant downtime. When troubleshooting a motor, I check for common issues like bad capacitors, shorted windings, or poor connections. Using a clamp-on ammeter, I measure the motor's current draw to ensure it is operating within its rated capacity. Replacing faulty components and ensuring proper lubrication and cooling can prevent future failures.

Control Systems: Industrial control systems, such as PLCs (Programmable Logic Controllers), require a deep understanding of both electrical and software components. When troubleshooting, I refer to the system's schematics and use diagnostic tools to test inputs and outputs. Identifying and correcting issues in the control logic or wiring can restore system functionality and prevent costly downtime.

Electrical troubleshooting is both an art and a science, requiring a combination of technical knowledge, practical skills, and a methodical approach. Whether I'm working on a residential, commercial, or industrial project, my goal is always to identify and resolve issues quickly and safely. By using the right tools, following best practices, and staying up-to-date with industry standards, I can ensure that electrical systems operate efficiently and reliably. If you're facing electrical issues, remember that professional help is just a call away. Stay safe and keep the current flowing!

Being a professional electrician, troubleshooting is an essential part of my daily routine. Whether I'm working on residential, commercial, or industrial projects, the ability to diagnose and fix electrical issues efficiently is crucial. In this blog post, I'll share my approach to electrical troubleshooting across different settings, highlighting the tools, techniques, and best practices that help me keep the lights on and the machines running smoothly.