What is Thermal Imaging?

Thermal imaging, also known as thermography, involves using infrared cameras to detect heat emitted by objects. These cameras convert heat into a visual image called a thermogram, which displays temperature variations in different colors. This technology allows us to see heat patterns that are invisible to the naked eye, making it easier to identify potential problems in electrical systems.

Residential Applications

In residential settings, thermal imaging is incredibly useful for identifying issues that could pose safety hazards or lead to costly repairs if left unchecked.

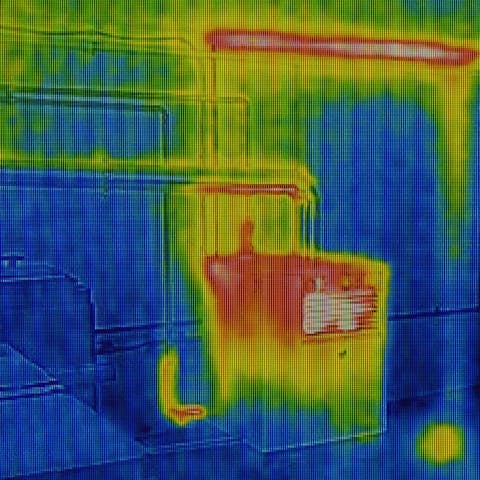

Detecting Electrical Hazards

One of the primary uses of thermal imaging in homes is to detect electrical hazards. Overloaded circuits, loose connections, and faulty wiring can all generate excessive heat, which can be a precursor to electrical fires. By scanning electrical panels, outlets, and wiring with a thermal camera, I can quickly identify hot spots that indicate potential problems. This non-contact method allows me to perform inspections safely without having to touch live electrical components.

Energy Efficiency

Thermal imaging is also valuable for improving energy efficiency in homes. Poor insulation, air leaks, and inefficient HVAC systems can lead to significant energy loss. By using a thermal camera, I can pinpoint areas where heat is escaping or entering the home, allowing homeowners to address these issues and reduce their energy bills.

Moisture Detection

Another common application is detecting moisture and water leaks. Water damage can cause serious structural issues and electrical hazards if it comes into contact with wiring. Thermal imaging can reveal hidden moisture behind walls and ceilings, enabling timely repairs before the damage becomes extensive.

We Use Thermal Imaging in Electrical Services and Here's How it Works.

Since I’m a professional electrician, I’ve seen firsthand how technology has revolutionized our field. One of the most significant advancements in recent years is the use of thermal imaging cameras. These devices have become indispensable tools in my toolkit, allowing me to diagnose and solve electrical issues more efficiently and safely. In this blog post, I’ll share how I use thermal imaging in residential, commercial, and industrial applications, and why it’s a game-changer for electrical work.

Commercial Applications

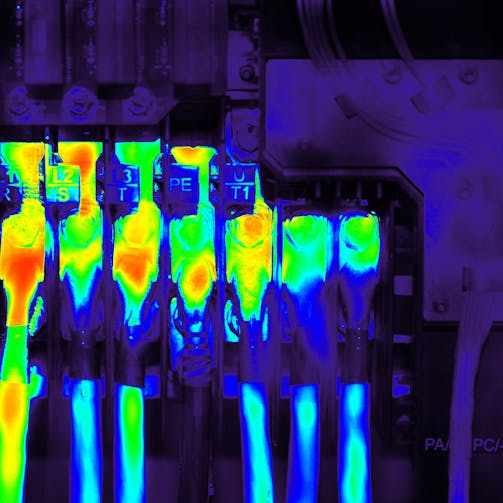

In commercial settings, the stakes are higher due to the complexity and scale of electrical systems. Thermal imaging helps ensure the safety and reliability of these systems, which are critical for business operations.

Preventive Maintenance

Thermal imaging is a cornerstone of preventive maintenance in commercial buildings. Regular thermal scans of electrical panels, switchgear, and other high-load connection points can identify issues like loose connections, overloaded circuits, and phase imbalances before they lead to equipment failure or downtime. This proactive approach helps businesses avoid costly repairs and interruptions to their operations.

Compliance and Documentation

Many commercial facilities are subject to stringent safety and compliance regulations. Thermal imaging provides a non-intrusive way to inspect electrical systems and document their condition. The images and data captured during inspections can be used to demonstrate compliance with safety standards and support insurance claims in case of electrical incidents.

Real-Time Monitoring

Advanced thermal imaging systems offer real-time monitoring capabilities, which are particularly beneficial for industries that require continuous operation, such as data centers and manufacturing plants. Real-time monitoring allows for the immediate identification and resolution of issues, minimizing operational disruptions and enhancing system reliability.

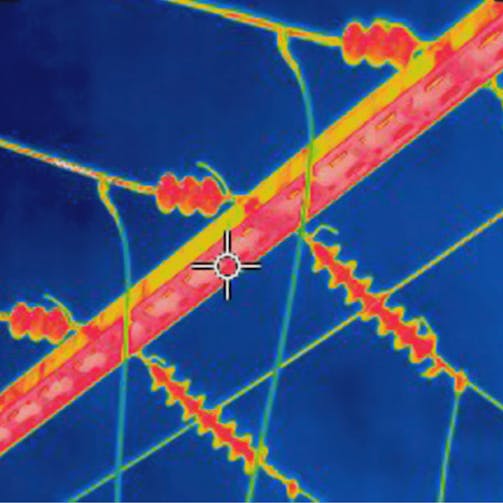

Industrial Applications

In industrial environments, thermal imaging is essential for maintaining the safety and efficiency of complex electrical systems. These settings often involve high-voltage equipment and critical infrastructure, where failures can have severe consequences.

Identifying Hot Spots

Thermal imaging is crucial for identifying hot spots in industrial electrical systems. Components like transformers, motors, and circuit breakers can overheat due to high resistance, excessive current flow, or insulation breakdowns. By scanning these components with a thermal camera, I can detect abnormal heating patterns and address issues before they lead to equipment failure or safety hazards.

Predictive Maintenance

Predictive maintenance is another key application of thermal imaging in industrial settings. By regularly monitoring the thermal profiles of electrical equipment, I can predict when components are likely to fail and schedule maintenance accordingly. This approach helps extend the lifespan of equipment, reduce downtime, and optimize maintenance schedules.

Enhancing Safety

Safety is paramount in industrial environments, and thermal imaging enhances it by allowing non-contact inspections. This reduces the risk of electrical shock and arc flash incidents, which can occur when working with high-voltage equipment. Thermal imaging also helps identify potential fire hazards by detecting overheating components before they reach dangerous temperatures.

Conclusion

Thermal imaging has transformed the way I approach electrical work, providing a powerful tool for diagnosing and solving issues across residential, commercial, and industrial applications. Its ability to detect heat patterns and identify potential problems early on makes it invaluable for ensuring safety, improving energy efficiency, and maintaining the reliability of electrical systems. Whether you’re a homeowner, business owner, or industrial operator, incorporating thermal imaging into your maintenance strategy can save you time, money, and headaches down the line. If you haven’t yet explored the benefits of thermal imaging, now is the time to do so. It’s a technology that truly makes a difference in the world of electrical work.